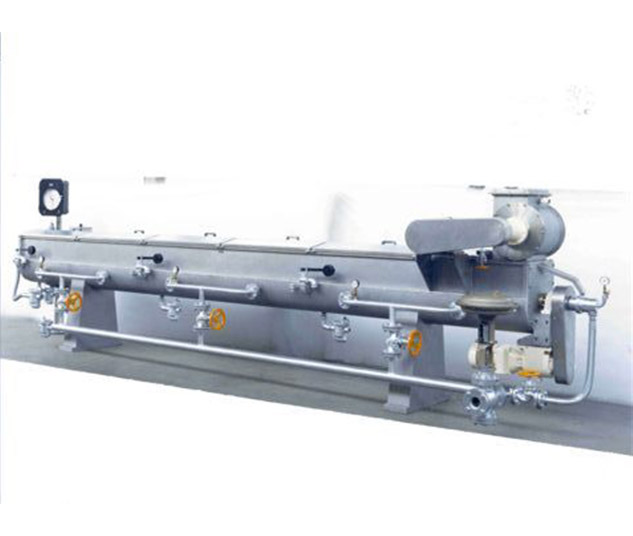

Continuous cooker with cochlea screw

The continuous cooker with screw feeder for product in pieces has a productive capacity of about 1500-2000 kg/h depending on the initial and final conditions of the processed product. It is constituted by a receiving hopper with an extraction screw feeder, a “U” shaped body with double wall and central screw feeder for the product advancement and another final one for the product extraction. The product cooking with possible own liquid, takes place by direct and indirect steam heating by means of a screw feeder controlled by inverter; a second inverter allows to vary the cooking time. At the end of the machine there is another screw feeder to extract the cooked product, while the cooking liquid comes out of the overflow pipe and it can be sent to a liquids treatment plant. The setting control of the various temperatures, the speed variation of cochlea screws, the setting of the various recipes and a possible final phase of the plant automatic washing are started through a PLC.